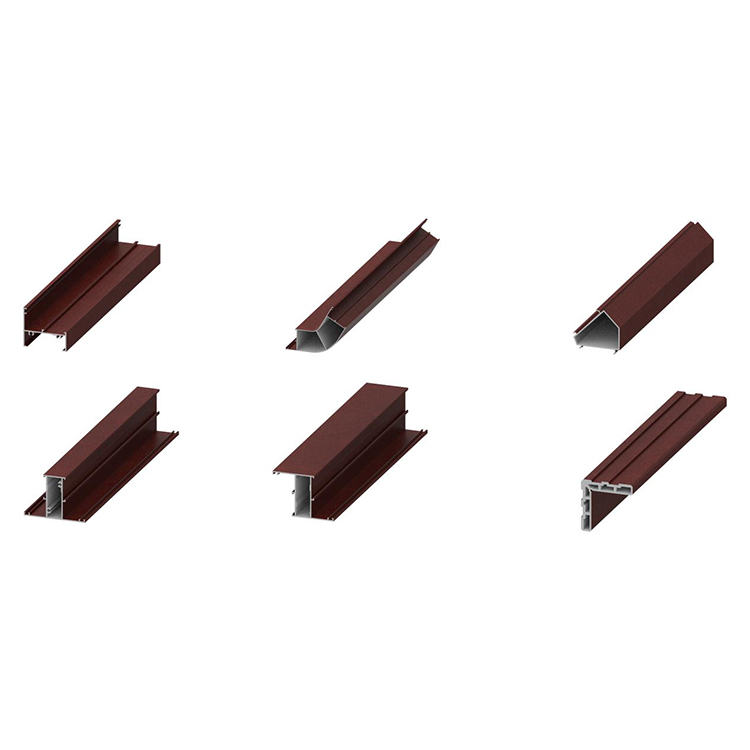

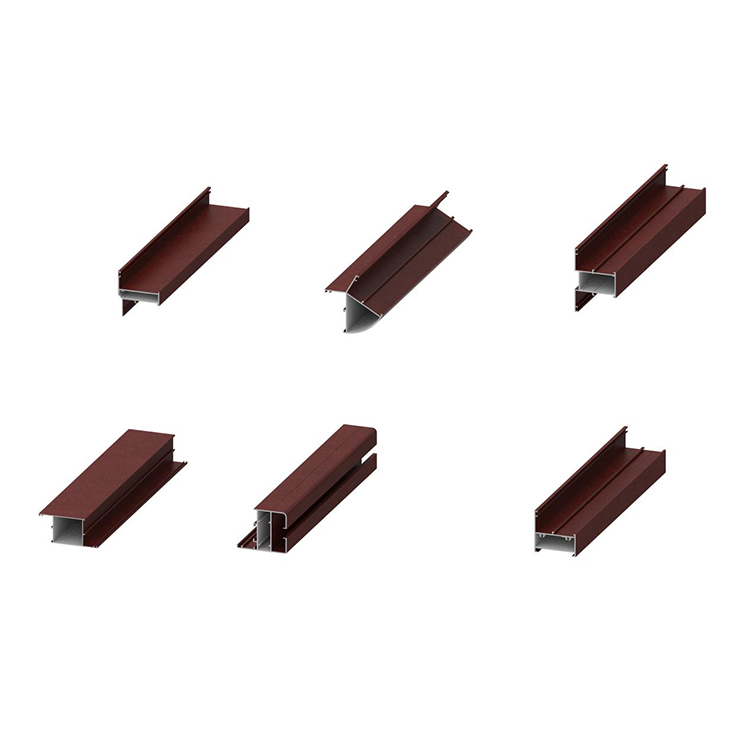

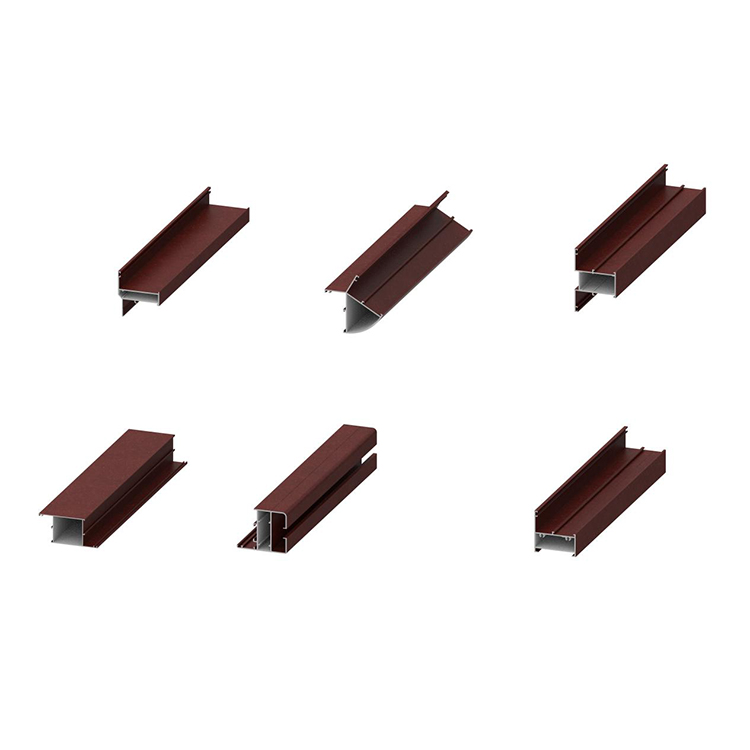

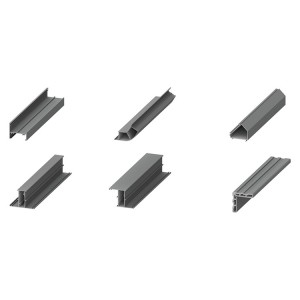

Aluminum profiles for Sliding Door

Major equipment: Extrusion machine, Powder coating machine, Shot blasting machine, Aluminum cutting machine, Anodized machine, Electrostatic coating machine, Fluorocarbon coating, Vertical coating wood, Transfer printing wood, Broken bridge thermal insulation, Glued thermal insulation section.

| Product name: | OEM factory price extruded aluminum profile for window and door |

| Material Grade: | Aluminum Alloy 6000 series:6063,6061,6060,6005 |

| Temper: | T3-T8 |

| Finish: | Anodised, powder coated, sandblasting, electrophoresis ,titanium Powder coating, Polish, Brushed, PVDF coating, wood-grained etc. |

| Color: | Silvery white, black, golden, champagne, dark bronze or according to your requirement |

| Shape: | Square, Round, Flat, according to customers' drawings |

| Thickness: | Above 0.8mm,the thicker the better |

| Mould: | 1. You can use our free mould 2. We open new mould as your drawing, it is free until your quantity enough. 3. The mould development time is usually 10 days. |

| Price | Aluminium Ingot price + processing Fee |

| Specification: | A. Length: ≤6.3m B. Normal Wall thickness: ≥1.0mm C. Normal Anodizing thickness: ≥10µm D. Normal powder coating thickness: 60-120µm E. Tensile strength: ≥160mpa F. Yield strength: ≥110mpa G. Extensibility: ≥8% H. Hardness(HW): 8-15 |

| Product Type: | We customize: extruded Aluminum profile of windows & doors frame,aluminum thermal break profile,curtain wall, aluminium shutter, aluminium partition profile, greenhouse profile, louver profile, aluminium industry profile, aluminum pipe,aluminium tube, U profile, T profile, etc |

| Applications: | Aluminum window and door, office partition,construction aluminum profile,aluminum pipe,industrial,Medical armrest/handrail, shutter, louver,garage door, curatin wall, sliding door, wardrobe door, kitchen cabinet,Aluminum curtain rail,aluminum hinge,aluminum rail |

| Packing details | Kraft paper, EPE Fram, Shrink film, Composite paper or as your need |

| MOQ: | Based on Size, 0.5-10tons |

| Delivery time: | 15-30 days if the mould is ready |

| Normal order sequence: | 1. Confirm the drawings, colors and price 2. Pay the mould fee and we start to make moulds 3. We send samples to you for your confirmation 4. Make the payment of 30% deposit, start production 5. Delivery |