In mid-19th century France, smelting aluminum technology was so backward that princes and ministers could only use silver cutlery at banquets. Only Napoleon II used aluminum bowls.With the application of electrolytic aluminum technology, aluminum more and more into the public life;With the development of surface treatment technology of aluminum alloy, aluminum metal with high practical value has aesthetic value.I’ve listed 6 common aluminum surface treatments. What else do you know?

Metals materials used more and more on the existing each kind of product, because the metal material more can reflect the product quality, highlight the brand value, and in many metals material, aluminum because of its easy processing, good visual effect, the surface treatment method is rich, the first adopted by each manufacturer, aluminum surface treatment is mainly divided into:Sand blasting (to create a matte pearl silver finish), polishing (to create a mirror finish), wire-drawing (to create a satin finish), electroplating (to cover other metals), and spraying (to cover other nonmetallic coatings).

Let’s take a look at the surface processing technology of aluminum and aluminum alloy in our daily products.

Sandblast

The process of cleaning and coarsening metal surfaces by the impact of high speed sand flow.This method of surface treatment of aluminum parts can make the surface of the workpiece to obtain a certain degree of cleanliness and different roughness, so that the mechanical properties of the surface of the workpiece are improved, so as to improve the fatigue resistance of the workpiece, increase the adhesion between it and the coating, prolong the durability of the coating film, but also conducive to the paint flow and decoration.This process is often seen in various Apple products, and is increasingly being used in existing TV cases or middle frames.

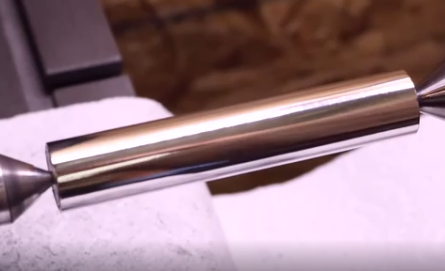

Polishing

A process in which the surface roughness of a workpiece is reduced by mechanical, chemical or electrochemical means to obtain a bright, flat surface.Polishing process is mainly divided into: mechanical polishing, chemical polishing, electropolishing.Aluminum parts using mechanical polishing + electrolytic polishing can be close to the stainless steel mirror effect, giving a person with high-grade simple, fashionable future feeling (of course easy to leave fingerprints but also more care)

Wire drawing

Wire drawing is the manufacturing process of repeatedly scraping an aluminum sheet out of the wire with sandpaper.Wire drawing can be divided into straight wire drawing, random wire drawing, spiral wire drawing, thread drawing.Metal wire drawing process, can clearly show every tiny silk mark, so that the metal matte in the spread of fine hair luster, the product has a sense of fashion and science and technology.

Highlights the cutting

The diamond cutter is reinforced by the engraving machine in the high speed rotation (general speed is 20000 RPM) of the engraving machine spindle to cut parts, resulting in local highlighting area on the surface of the product.The brightness of the cutting highlight is affected by the speed of the milling bit. The faster the bit speed is, the brighter the cutting highlight will be, while the vice versa.

High-gloss high-gloss cutting is especially used in mobile phones, such as iPhone5. In recent years, some high-end TV sets have adopted the high-gloss milling process for the metal frame. In addition, the anodic oxidation and wire drawing process make the TV full of fashion sense and sharp sense of science and technology.

Anodic oxidation

Anodic oxidation refers to the electrochemical oxidation of metal or alloy, aluminum and its alloy in the corresponding electrolyte and specific process conditions, due to the action of external current, in the process of forming a layer of oxide film on the aluminum products (anode).Anodic oxidation can not only solve the aluminum surface hardness, wear resistance and other aspects of the defects, but also can extend the service life of aluminum and enhance the beauty, has become an indispensable part of the aluminum surface treatment, is the most widely used and very successful process.

Two-color anodizing

Two-color anodizing refers to anodizing a product and giving a specific area a different color.The cost of two-color anodic oxidation is high because of the complexity of the process.But through the contrast between the two

Post time: Jul-03-2021