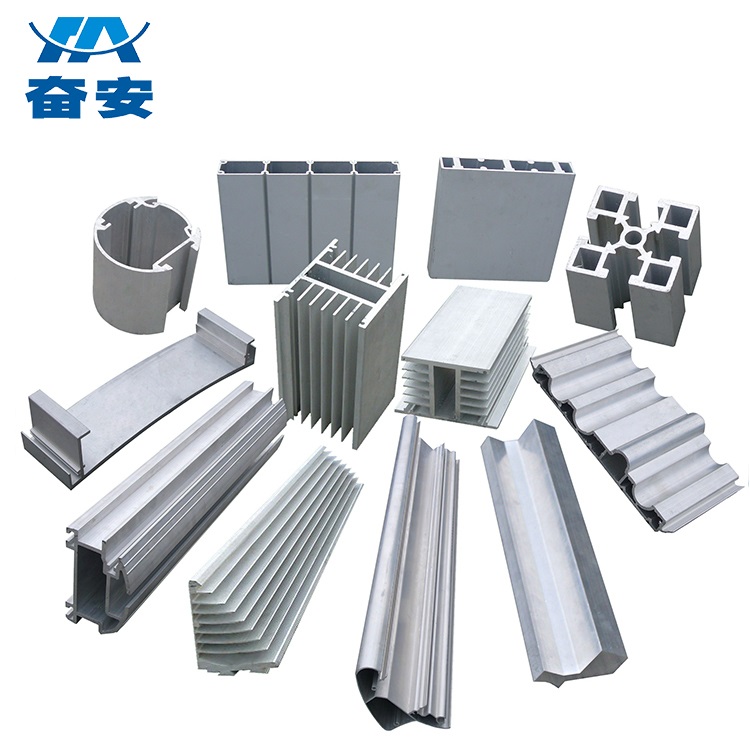

Aluminum is the third most abundant metal in the Earth’s crust, and the third most abundant element overall.Aluminum profiles are extruded from aluminum alloy and have different cross section shapes and sizes of a product can replace the stainless steel wood steel material and other products of the frame .No other metal can compare to Aluminum when it comes to its variety of uses. Some uses of aluminum may not be immediately obvious; for example, did you know aluminum is used in the manufacturing ?

Aluminum is incredibly popular because it is:

Lightweight

Strong

Resistant to corrosion

Durable

Ductile

Malleable

Conductive

Odorless

Aluminum is also theoretically 100% recyclable with no loss of its natural properties. It also takes 5% of the energy to recycle scrap aluminum then what is used to produce new aluminum.

The Most Common Uses of Aluminum

The most common uses of aluminum include:

Transportation

Construction

Electrical

Consumer Goods

Transportation

Aluminum is used in transportation because of its unbeatable strength to weight ratio. Its lighter weight means that less force is required to move the vehicle, leading to greater fuel efficiency. Although aluminum is not the strongest metal, alloying it with other metals helps to increase its strength. Its corrosion resistance is an added bonus, eliminating the need for heavy and expensive anti-corrosion coatings.

While the auto industry still relies heavily on steel, the drive to increase fuel efficiency and reduce CO2 emissions has led to a much wider use of aluminum. Experts predict that the average aluminum content in a car will increase by 60% by 2025.

①Aircraft components

Aluminium has three excellent properties in particular that make it so useful in the aviation industry.high strength to weight ratio, excellent ductility, and high resistance to corrosion. In fact, it is because of aluminium that human beings have been able to fly in the first place, ever since the Wright brothers used aluminium to make the engine crankcase for their first wood-frame biplane.

②Spacecraft components

The advancement of spacecraft and rocket technology is directly tied to the advancement of aluminium alloys. From the first prototype engines to NASA’s use of an aluminium-lithium alloy, this material has been part of the space program since its inception.

③Ships

Light and strong materials bode well for ships, especially ones that fill the hull with cargo. Aluminium’s lightweight properties allow for more surface and less mass – without compromising the strength that is necessary to withstand cracks and breaches in the hull.

④Trains

Trains can function very well using iron and steel, as they have for centuries. But why not improve upon a design if you are able to do so? Using aluminium components in place of steel can have advantages: aluminium is easier to form and improves efficiency.

⑤Personal vehicles

Whether it is personal vehicles, like an average Ford sedan, or a luxury car model, like a Mercedes Benz, aluminium is increasingly the “material of choice” for automobile manufacturers due to its strength and environmental advantages.

Vehicles can be lighter and more nimble without losing out on strength or durability. This is also advantageous as cars can be more easily recycled, adding a level of sustainability to using aluminium in vehicles.

Construction

Buildings made with aluminum are virtually maintenance free due to aluminum’s resistance to corrosion. Aluminum is also thermally efficient, which keeps homes warm in winter and cool in summer. Add the fact that aluminum has a pleasing finish and can be curved, cut and welded to any desired shape, it allows modern architects unlimited freedom to create buildings that would be impossible to make from wood, plastic, or steel.

①High-rise buildings

With its high malleability, high strength to weight ratio, and versatility, aluminium is a valuable material at the heart of high-rise buildings and skyscrapers. It is also an ideal material because of its durability, design flexibility, and contributions to energy savings, both front-end and back-end.

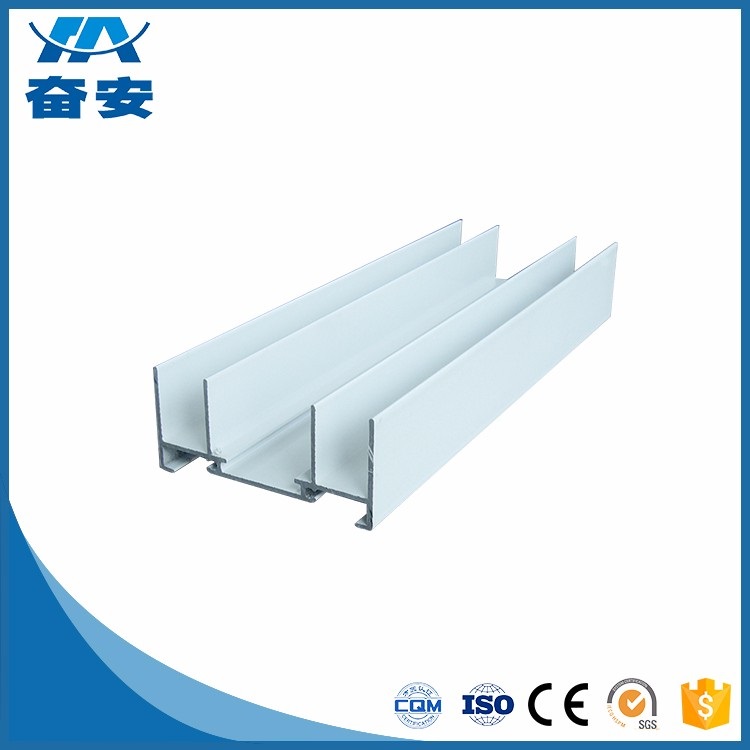

②Windows and doors’ frames

Aluminium frames are generally a quite durable, cost-effective option for homes and offices. They are also lightweight and can be made impact-resistant, which is useful in places that experience high winds and powerful storms.

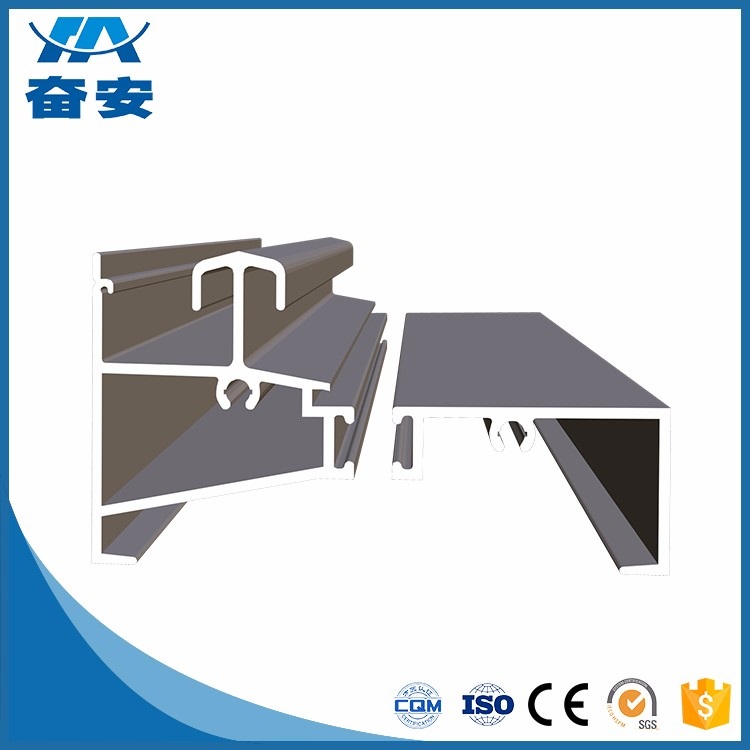

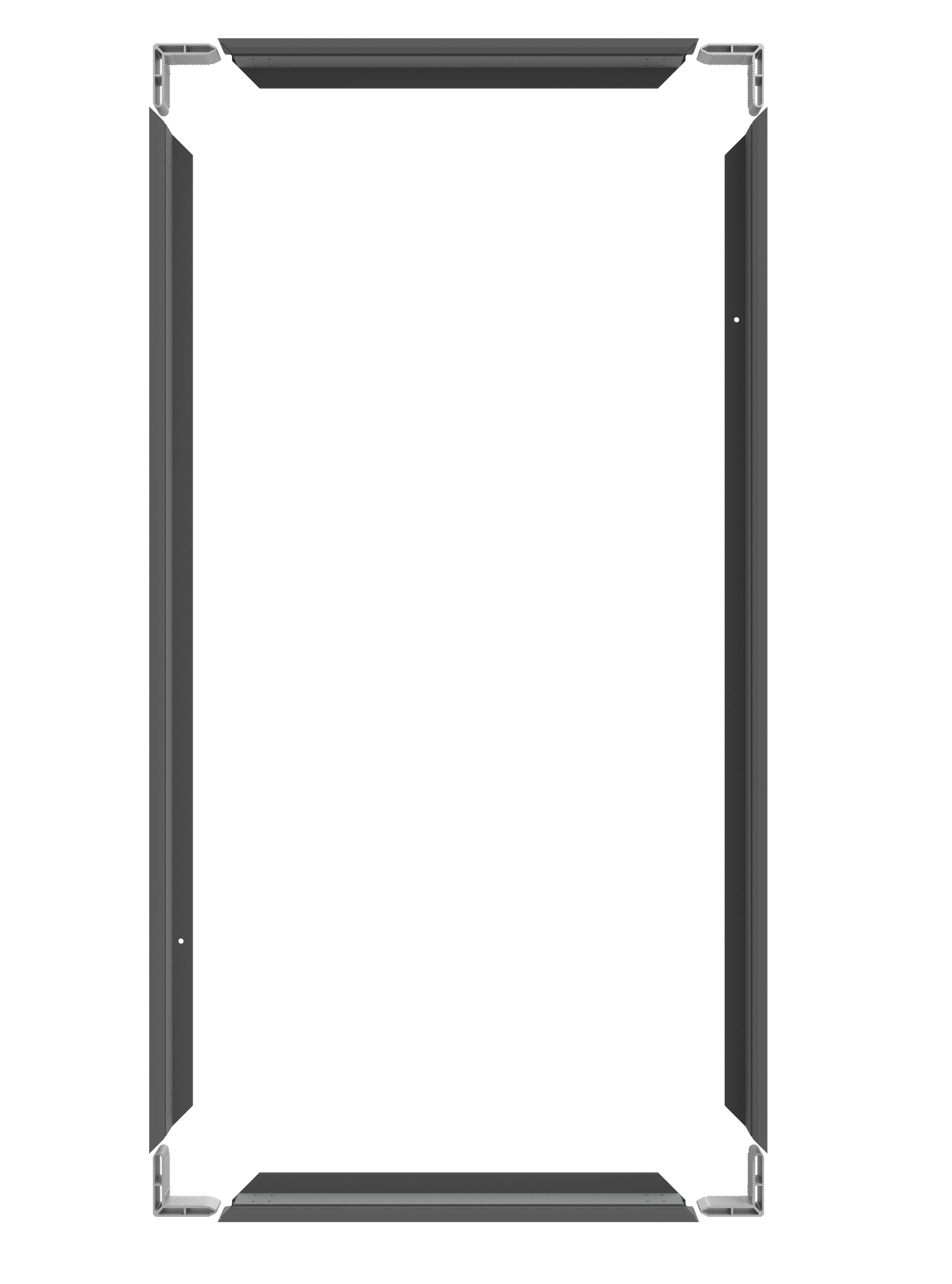

③Solar Frames

This is our PV frame system, which is an aluminium frame system to protect solar cell panel.Various surface finished not only ensure the intensity of frame system, but also strengthen the functions and visual effect.Unique interface makes the installation easy and convenient.A number of frame specifications can meet different integration by customer.

Normally , we use 6063 or 6060 ,T5 or T6 for the frames. What kinds of surface treatment we can make? Anodized ,powder coating, electrophoresis and Sandblasting.we design drainage holes and rigid construction to prevent the frame from deforming and breaking.

Using aluminium for window frames is usually lower-maintenance and less expensive than wood, and is also more resistant to scratching, cracking, and marring. However, one of the major disadvantages of using aluminium frames is that they are not as energy efficient as wood, nor do they offer the same level of insulation.

Electrical

Although it has just 63% of the electrical conductivity of copper, aluminum’s low density makes it the best option for long distance power lines. If copper was used, support structures would be heavier, more numerous, and more expensive. Aluminum is also more ductile than copper, enabling it to be formed into wires much more easily. Lastly, its corrosion-resistance helps protect wires from the elements.

Aluminium has barely more than half the conductivity of copper-but with only 30 percent of the weight, a bare wire of aluminium with similar electrical resistance will weigh only half as much. Aluminium is also less expensive than copper, which makes it more attractive from an economical and financial perspective.

In addition to power lines and cables, aluminum is used in motors, appliances, and power systems. Television antennae and satellite dishes, even some LED bulbs are made of aluminum.

Consumer Goods

Aluminum’s appearance is the reason it is used frequently in consumer goods.

Smartphones, tablets, laptops, and flat screen TVs are being made with an increasing amount of aluminum. Its appearance makes modern tech gadgets look sleek and sophisticated while being light and durable. It is the perfect combination of form and function which is critical for consumer products. More and more, aluminum is replacing plastic and steel components, as it is stronger and tougher than plastic and lighter than steel. It also allows heat to dissipate quickly, keeping electronic devices from overheating.

Apple’s Macbook

Apple uses predominantly aluminum parts in its iPhones and MacBooks. Other hi-end electronics brands like audio manufacturer Bang & Olufsen also heavily favor aluminum.

Interior designers enjoy using aluminum as it’s easy to shape and looks great. Furniture items made from aluminum include tables, chairs, lamps, picture frames and decorative panels.

Of course, the foil in your kitchen is aluminum, as well as pots and frying pans which are frequently made from aluminum. These Aluminum products conduct heat well, are non-toxic, resistant to rust, and are easy to clean.

Aluminum cans are used to package food and beverages. Coca-Cola and Pepsi have been using aluminum cans since 1967.

Metal Supermarkets

Metal Supermarkets is the world’s largest small-quantity metal supplier with over 85 brick-and-mortar stores across the US, Canada, and United Kingdom. We are metal experts and have been providing quality customer service and products since 1985.

At Metal Supermarkets, we supply a wide range of metals for a variety of applications. Our stock includes: stainless steel, alloy steel, galvanized steel, tool steel, aluminum, brass, bronze and copper.

Our hot rolled and cold rolled steel is available in a wide range of shapes including: bars, tubes, sheets and plates. We can cut metal to your exact specifications.

Post time: Apr-30-2021